In many industries, the quality of the end product is a direct consequence of its healthiness, and therefore of micro-organisms.

This is true for a distillery, but also for wineries, breweries or food industries. That’s why we need to introduce the topic of Cleaning In Place systems (often abbreviated to "CIP").

In this short guide we will look in detail at what a Cleaning in Place system - the "cleaning without disassembly" - is and what advantages it brings in terms of cost-effectiveness and efficiency.

To do this, we will start with talking about cleaning, particularly on distilleries, breweries and wineries.

Index

What we mean by hygiene

The World Health Organisation defines hygiene as the "conditions and procedures that help maintain health and prevent the spread of disease".

Many bad conditions are out of poor hygiene management in a distillery, brewery, winery or food industry, i.e.:

- Variable and non-optimised performance in the raw material fermentation.

- Decreased organoleptic quality of the fermented substrate, with direct impact on the product.

- Less safe working environment (e.g. slippery floors due to spills).

- Poor alcohol yield.

To-know: Microorganisms are a steady presence in the environments and equipment of the plants. We are not only talking about those in the environment, but also those introduced with the raw material: cereals, grapes, molasses, etc. all have a natural bit of microorganisms.

Luckily, pathogenic microorganisms do not survive the production phase, because of the temperature and the high concentration of ethanol. However, they can have a serious impact on the quality of our product.

Let us consider two groups of microorganisms: bacteria and ‘wild’ yeasts.

1.1. Bacteria

It is impossible to talk about cleaning-in-place systems without mentioning bacteria. Many can survive and thrive in the raw material treatment and fermentation phases. The main ones are Lactic Acid Bacteria (LAB), in particular Lactobacillus (rod-shaped) and Pediococcus (round-shaped).

In the production of certain spirits (whisky, rum) the presence of LAB is essential for the production of certain flavours, but an excessive amount of LAB is not desirable. It leads to a pH decrease during fermentation, or to slowed or blocked fermentations, and consequently a reduction in yield and the presence of undesirable aromas.

Attention must also be paid to the presence of Enterobacter and Escherichia bacteria from water sources contaminated with faecal matter. Although these bacteria do not survive at alcohol contents above 2% ABV and pH below 4.6, they can survive long enough to give undesirable flavours (e.g. parsnips) to the fermentation.

Other bacteria of interest are:

- Acetobacter and Gluconobacter: they convert ethanol to acetic acid.

- Leuconostoc mesenteroides: present in molasses, it can synthesise very viscous dextrans (branched polymers of glucose). This causes problems in pumping and piping.

- Zymomonas: produces undesirable aromas from fructose.

1.2. Wild yeasts

By 'wild yeasts' we mean any yeast that has not been deliberately inoculated into the fermentation medium. This can also include other yeast strains used in other processes.

These different yeasts can:

- produce different aromas during fermentation.

- have different fermentation yields.

- interfere with and inhibit the actual fermentation process.

1.3. Managing the microorganisms

Fortunately, we do not need to destroy all microorganisms. We can simply reduce their number to a level compatible with the efficiency of the process and the quality of the product, and keep this level stable. This can be achieved through routine cleaning processes, good design, hygienic practices and process control.

The purpose of cleaning is to remove not only microorganisms, but also any available nutrient source from equipment and piping. The cleaning in place (CIP) system is very popular because of its extreme adaptability, which makes it suitable for all these different uses.

2.1. What is a Cleaning In Place system

The Cleaning In Place (CIP) process is defined as the process of cleaning the interior of machines without removing or dismantling parts of the equipment.

The modern Cleaning In Place (CIP) systems installed - which are installed in distilleries, breweries, wineries and food processing facilities - are closed systems that clean the plant sections with different levels of automation. This allows safe, efficient and cost-effective cleaning. Otherwise, complex equipment disassembly and manual cleaning would be required.

2.2. How to determine the effectiveness of cleaning in place

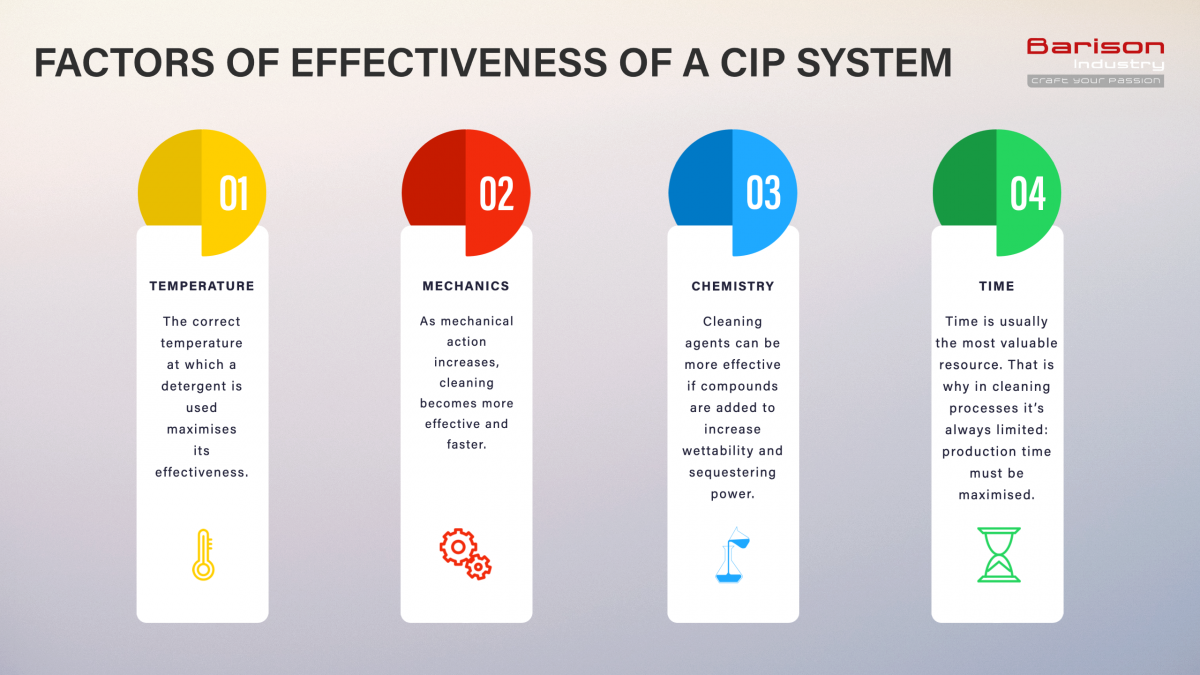

The effectiveness of a CIP system first relies on four factors: mechanical action, chemical action, temperature, time for cleaning-in-place.

These four factors must be considered altogether: any reduction in one of the quadrants in cleaning in place must be balanced by increasing one or more of the other factors.

2.2.1 Mechanical action

Mechanical action is the physical removal of contamination by the action of pressure or by generating a turbulent flow. As mechanical action increases, cleaning becomes more effective and faster.

In the distillery/winemaking/brewing this action is carried out by flushing high-velocity cleaning fluids into the pipes and by the use of high-pressure cleaning nozzles in the tanks.

2.2.2 Chemical action

The type, formulation and concentration of cleaning chemicals are important. Cleaning agents can be more effective if compounds are added to increase wettability and sequestering power, i.e. the ability to bind metal ions that can cause scale.

2.2.3 Temperature

The correct temperature at which a detergent is used maximises its effectiveness. However, too high a temperature may cause decomposition and precipitation of dissolved solids.

Too high a temperature can "cook" the bad agents, making them even more difficult to clean.

2.2.4 Time for cleaning-in-place

Time is usually the most valuable resource. That is why in cleaning processes it’s always limited: production time must be maximised. Therefore, the need for fast cleaning cycles is usually compensated for by increasing the impact of the other three factors of the CIP system.

CIP system design

When choosing and planning/designing the CIP system, several core factors must be taken into account:

- Centralised vs. decentralised installation: first, the size of the plant, the presence of several sections requiring CIP, the volumes of equipment to be cleaned must be considered. Second, it is necessary to evaluate the managerial and economic effectiveness of a single centralised CIP section. Or, alternatively, multiple smaller sections can be located close to the equipment to be cleaned.

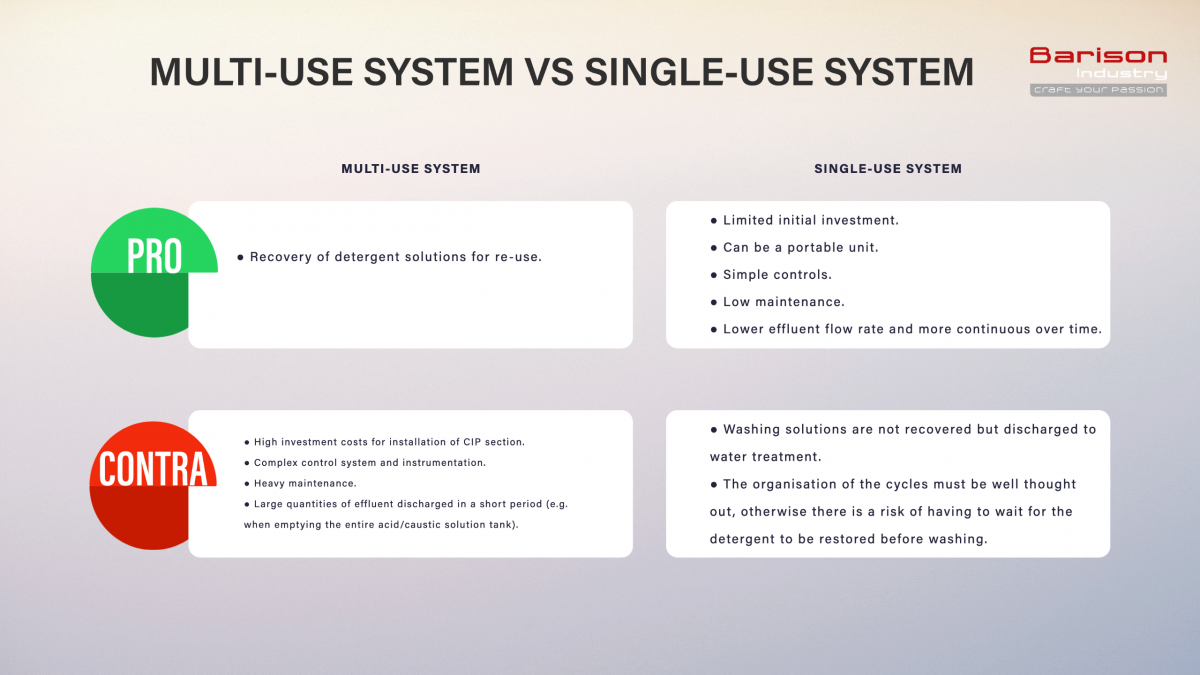

- Single-use CIP vs multi-use CIP: In the single-use scheme, cleaning and rinsing solutions are not recirculated, recovered and reused as in the multi-use scheme. The recirculated reagent contains solids removed during the cleaning process, as well. Therefore, in-line filters (typical mesh size: 400 microns) can also be provided to increase the life of the detergent.

3.1. Dead legs

Both in the design phase of a new system and in an existing one, it is important to analyse the number and size of "dead legs".

Dead legs are those sections of pipework where the liquid can stagnate and the flushing solution does not have easy access. The microorganisms that accumulate and stagnate at these points are only marginally affected by the flushing procedures, and thus become a source of contamination in further productions.

The overall development of the pipes is often very large, as is the number of valves, instruments and branches. Critical issues can only be identified after a strict analysis of the liquid production and transfer phases, carried out by a person who knows both the plant and the process.

In more complex cases, tools such as 3D modelling and CFD (Computational Fluid Dynamics) studies help to understand the impact of CIP on the cleanliness of pipes and equipment.