Irish and Scottish single malts are part of the common knowledge as the oldest and most globally recognized whiskeys; these are distilled products derived from barley malt. To be distilled, the barley malt grain must go through several stages that will allow it to produce the wort (a mixture of water and ground malt), which later, through fermentation, will become wash-ready to be distilled.

The characteristics of barley and the production of malt

In the malting process, ideal conditions are established by which the barley grain can begin sprouting. The purpose of malting is to stimulate the production of saccharification enzymes without consuming too much starch in the process.

The process must be stopped when the barley grain reaches the right degree of germination. If left unchecked to germinate, the barley grain consumes all the starch to support the plant's growth until it can perform photosynthesis.

To stop the germination process, the seed is then dried. Drying temperatures vary depending on the type of malt to be obtained.

Scotch Whisky was traditionally dried over wood fires or peat (peat); nowadays, malted barley is dried with hot air and peat essence (peat reek) is added later.

The most critical enzymes produced during malting that will later serve in the transformation of starch into fermentable sugars are:

- α-amylase, from which dextrins are obtained;

- β-amylase, from which maltose is obtained;

- limit dextrinase, an enzyme that breaks bonds at branching points and originates dextrins;

- maltase (aka amyloglucosidase), breaks bonds in maltose, maltotriose and maltotetraose to originate glucose.

Milling

Before moving on to the stage of converting starches into sugars, an operation performed in the mash tun and lauter tun, the malt produced through malting must be fragmented into smaller parts (a homogeneous "grist" flour can be made that contains all aspects of the barley grain, including rind and fragments of different sizes).

In Scotch Whisky production, the particle size distribution of the milled grain is influenced by the equipment used in milling. Milling primarily aims to make the starch accessible to the enzymes that will convert it into fermentable sugars. The most common are dry roller mills, typically with 2, 4 or 6 pairs of rollers, depending on the distillery's production capacity.

The grain size classes resulting from the classical mills are:

- flour: flour, the finest fraction;

- grits: "semolina," itself divided into coarse and fine;

- husk: tegument of the grain, will be used as a filter to separate the wort.

Mashing and wort separation

Wort is the resulting product of mixing water and malt flour/grist with fermentable sugars within it produced by the division of starch by enzymes. The mashing process is used to produce wort.

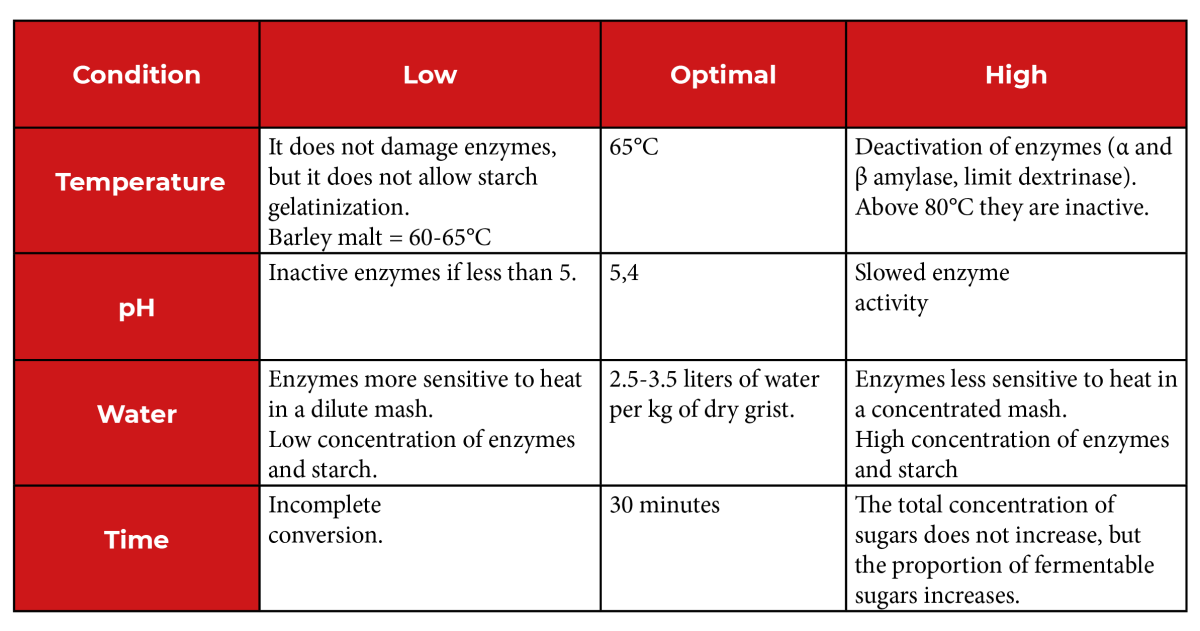

The purpose of mashing is to transform the starch in the grist (or flour) into fermentable sugars through the introduction of water and mixing under certain specific environmental conditions. Specific machinery is used to do this: the mash tun and the lautern tun.

Main components of Mash Tun:

The mash tun is a generally insulated tank, complete with direct or indirect steam heating system, water/grist mixer, and possibly the pre-masher, which allows for better amalgamation of water and grist before processing to convert starches to sugars.

Mash Tun process:

Water and grist are introduced inside the mash separately: first the water and then the grist, or together; if the pre-masher is installed, the two compounds inside the mash are mixed and heated until the ideal temperature for starch conversion is reached. Once the conversion is done, the mash will be sent to the lauter tun for further processing, that is, the separation of solid from liquid, an operation typical of Ireland and Scotland.

Main components of Lautern Tun:

The Lautern Tun is a generally insulated tank with a blade system for cutting the bed of grains during filtration. A system that also allows the draining of the grains themselves when exhausted, it is also equipped with a double perforated filter bottom for separating the liquid from the grains and a system for visually checking the turbidity of the extracted wort, a method for washing the grains to remove the last sugary parts (grist hydrator) and, eventually, the pre masher, which allows for the better amalgamation of water and grist before processing to convert starches into sugars.

Mash tun's process on its own:

Water and grist are introduced inside the mash separately: first the water and then the grist, or together if the pre-masher is installed. The two compounds inside the mash are mixed and heated until the ideal temperature for starch conversion is reached.

Next begins the second stage of separating the liquid from the grains: the liquid percolates under the perforated bottom that holds the bed of grains, is put back above the bed of grains until it reaches ideal clarity, and then is transferred to the fermenters. In transferring to the fermenters, the liquid is cooled to a temperature suitable for fermentation. Toward the end of the extraction, new water at a temperature of 70° is placed inside the lautern and above the bed of grains for the final washing of the grains and to perform the extraction of the last residual fermentable parts.

Process of Lautern Tun in copy with Mash:

The mash produced in the Mash is transferred and loaded into the lautern by free fall or through a pump with coupling piping.

Next begins the second stage of separating the liquid from the grains: the liquid percolates under the perforated bottom that holds the bed of grains, is put back above the bed of grains until it reaches ideal clarity, and then is transferred to the fermenters. In transferring to the fermenters, the liquid is cooled to a temperature suitable for fermentation. Toward the end of the extraction inside the lautern and above the bed of grains, new water at a temperature of 70° is introduced for the final washing of the grains and to perform the extraction of the last residual fermentable parts.

The Grant to perform underback in the Lautern/Mash tun, "high turbidity wort replacement"

The volume below the perforated false bottom of the Lauter tun is relatively shallow.

Sucking directly from this space with the wort discharge and transfer pump exposes the risk of disturbing the layer of solids deposited above the perforated bottom-solids that, if compacted do not allow filtration and liquid passage. To avoid this problem, the Grant is used. The Grant is a small tank with special arrangements placed lower than the bottom to receive free-falling liquid from the bottom of the Lautern/Mash tun. At the outlet of the Grant with a level suction pump, it is possible to transfer the liquid above the brewers, an operation also called underback, or to the cooling system and then to the fermenters (if the degree of turbidity is within the expected value).

Conclusion

We have seen how a grain of barley is transformed into the raw material used to produce the famous Irish malt and scotch whiskey. The mash tun and lautern tun are key in this process, allowing fermentable sugars to be extracted under ideal conditions.

Many variables are involved in efficiency and optimal yield, and in your distillery project, you will need professionals who can guide you toward the best solution.