Analysis

We analyze your requests, identifying the best solutions. We start from a study on raw materials, quantity and quality of the product required and size of the plant, identifying the types of plant suitable for your needs and all the technical specifications that can allow excellent results in efficiency and quality.

Thanks to collaborations with specialized laboratories we can analyze the raw materials to give a precise and accurate feedback on the feasibility of using the material itself for the production of a given product.

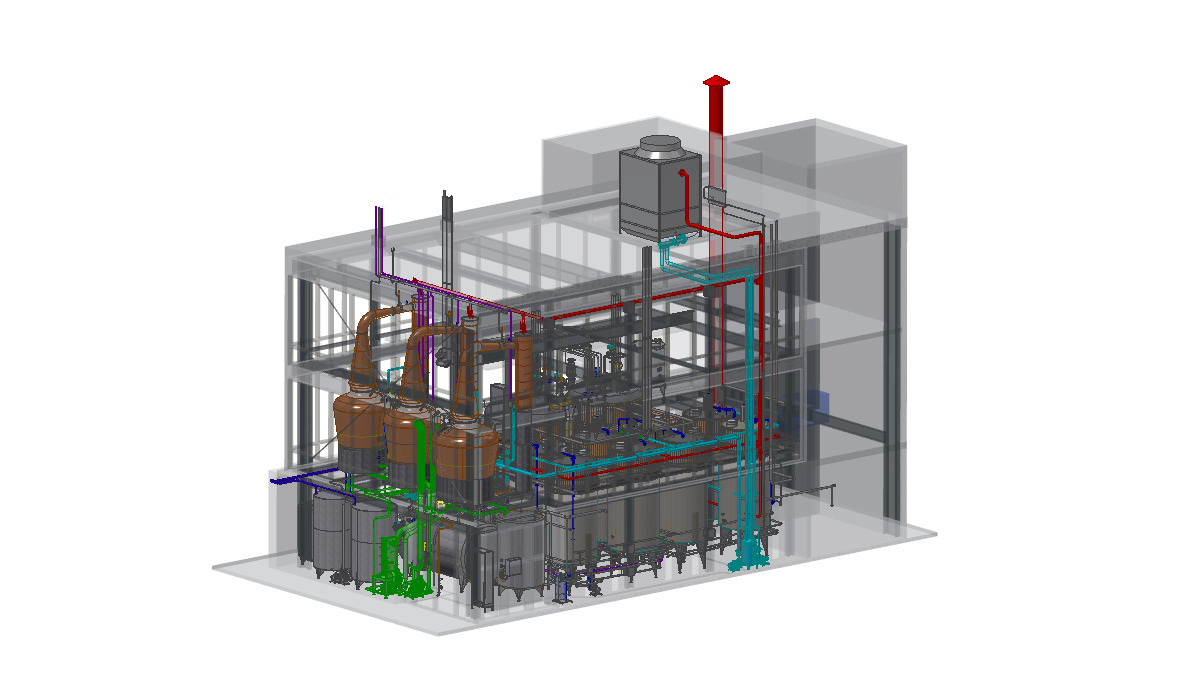

Design

Through the most sophisticated software, we design all our projects in our technical office, paying particular attention to the ease of use, efficiency and aesthetics of the system. We create 3D models so you can see the plant before production. 3D models allow precise and accurate inspection of each product's components, facilitating production and and on-site installation.

Our know-how allows us to provide turnkey plants, carefully studied in every detail. Starting from a simple idea we can provide you with everything you need to start or expand your production.

Manufacture

Each plant is built in our factories with the best materials on the market and the best technologies.

We do not have mass production, each plant is unique and different. For this reason every detail is taken care of to the utmost: quality components, care of surface finishes, care of aesthetics, care of welding and optimization in the positioning of the entire plant thanks to 3D design, are just some examples of how our supplies can stand out on the market.

The plants are designed and built to guarantee maximum simplicity of use even in manual conditions, starting from the position of the various controls (valves, measuring instruments) up to the management software able to control the plants remotely, through a customized automation in aesthetics and functionality, which allows both easy use of the equipment and the saving of the various recipes.

Installation

The installation of the products is carried out at your plant by specialized personnel. This allows to reduce the time between the realization of the plant and the first production cycle.

The transport of the goods can be taken care of by our logistic department that selects the best carriers, in order to guarantee the timely arrival of the plants on site, and to eliminate all the problems related to the documents needed for transport and collection.

To ensure the integrity of the equipment, the transported goods are packaged with ISPM15 treated wood and heat shrinking nylon.

All plants, after installation, are tested by checking that all equipment is working properly and showing you the procedures for easy and efficient use.

Assistence

Our priorities are the quality of service and innovative technology, as well as providing you with high quality on safety and environmental standards, excellence in plant performance and optimized delivery times.

We have always been focused on your needs. During each test we show you all the procedures for the correct functioning of the equipment. This helps to instruct your operators who are able to understand and manage the operation of each plant perfectly. The technical team is at your disposal for maintenance services throughout the life of the plant.

The efficiency of the plants is the first corporate objective. We don't want to be a simple supplier, but a reliable partner who follows you 360° and finds the optimal solutions for every need.

Do you want to get a free consultation?

Leave your details to receive a free consultation We'll get back to you in a few hours!

Alternatively you can contact us at +39 0461 1788800